Hot Line

88910291

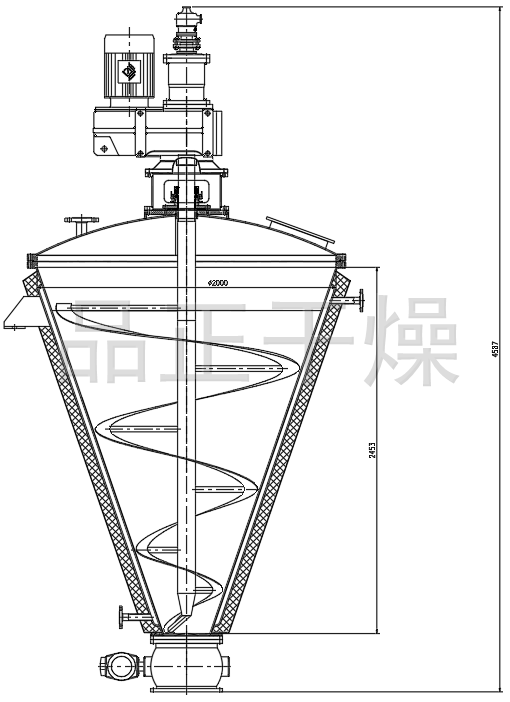

1、 Working principle

The heating cone is equipped with a heating jacket, and the heat source is hot water, heat transfer oil or low pressure steam, so that the inner wall of the cone can maintain a certain heating temperature. During operation, under the action of vacuum pump, certain vacuum conditions are maintained in the machine. The drive system drives the spiral belt mixing device to rotate (heating can be set at the same time), and the material under the action of mixing constantly turns inside the equipment, and fully contacts with the inner wall of the cone to realize heat transfer, so that the water inside the material is continuously evaporated, and the water vapor is led out by the vacuum pump and collected by the condenser. After drying, open the lower discharge valve to discharge.

2、 Product characteristics

Need to dry at lower temperature

The final moisture content is particularly low

The combined water needs to be evaporated

Solvent recovery

Toxic, flammable and explosive products

3、 Equipment features

●The material in the machine is heated in the container and is close to the inner wall of the container. The propeller blade rotates from bottom to top to the upper part of the container, and then flows in a vortex direction along the main axis. The material is always in dispersion during the whole drying process. The motion state of the material ensures the balanced heating of the material.

●The dust device of the machine is installed at the connection between the upper part of the container and the vacuum pipe orifice. It is not easy to be blocked by flying materials during drying. The dust collector is equipped with a blowback device, which can blow back the materials adsorbed in the dust collector at any time during the drying process, ensuring that the vacuum pumping pipeline is unblocked.

●The machine can be manually fed or vacuum fed, and can be used with the relevant feeding device. The blocking valve can be configured with electric opening or manual opening according to the user's needs, and the air purging device can be pretended according to different needs.

●The machine has simple overall structure, simple maintenance, convenient cleaning, and online cleaning or sterilization. The computer automatic control system can be configured according to customer needs. Each batch of materials realizes accurate process control.

●The inner wall adopts cutting-edge technology to ensure that materials with poor fluidity do not stick to the wall, and at the same time achieve optimal heat transfer efficiency.

4、 Scope of use

It is mainly applicable to the concentration, crystallization and drying of materials in the corresponding processes of chemical, pharmaceutical, feed and other industries. Such as resin powder, fermentation promoter, cellulose, pharmaceutical and chemical raw materials.

Traditional equipment | Single cone vacuum dryer | ||||||

Equipment name | Loading capacity(L) | Drying time(H) | Material form (existing after drying) | Loading capacity(L) | Drying time(H) | Material form (after drying) | Residual solution (or water) |

Double cone dryer | 300 | >22 | Globular agglomeration | 600 | 7 | Completely powdery |

|

Double cone dryer | 140 | 48 | Globular agglomeration | 400 | 12 | Completely powdery |

|

Double cone dryer | 140 | 48 | Globular agglomeration | 400 | 12 | Completely powdery |

|

Disc oven | 290 | 48 | Bulk | 600 | 10 | Completely powdery |

|

Disc oven | 290 | 19 | Bulk | 500 | 7 | Completely powdery |

|

Double cone dryer | 300 | 12 | Globular agglomeration | 600 | 6 | Completely powdery |

|

Double cone dryer | 400 | 28 | Bulk | 650 | 8 | Completely powdery |

|

Double cone dryer | 400 | 22 | Bulk | 650 | 10 | Completely powdery |

|

Multiple devices | 250 | >150 | Thick plate | 500 | 45 | Completely powdery |

|

Bake out furnace→Double cone dryer | 400 | >80 | Thick-grained | 450 | 8 | Completely powdery |

|

Double cone dryer | 440 | 22 | Bulk | 500 | 8 | Completely powdery |

|

Multiple devices | 300 | 72 | Graininess | 500 | 27 | Completely powdery | |