Hot Line

88910291

The unit inherits the traditional granulation process and combines the wet granulation, boiling drying preparation and wet finishing units scientifically and effectively according to the process characteristics to form a complete solid preparation production linkage line. This linkage unit retains the independent use function of each single unit, while the particle hopper with high viscosity is equipped with a pipeline hot air curing device. The production efficiency and automation of the equipment have been greatly improved. This greatly reduces the labor intensity of workers, simplifies the drug preparation process, improves the drug yield, and avoids the secondary pollution in the drug production process. Meet GMP requirements.

Characteristic

PLC control, high automation, convenient operation and maintenance

Full-automatic sealed loading and unloading system, pipe-type connection, quick-opening clamp connection, no dead angle, convenient disassembly and easy cleaning

The equipment is designed according to the withstand voltage standard of 2 bar, and all parts of the whole machine have good grounding mode

Cart-type granulator head, convenient and flexible installation

Made of stainless steel, 304/316 high-quality stainless steel is used for the parts in contact with materials

Application scope of this set of production line

1、Tablets, granules (granules), capsules

2、Low-sugar, sugar-free, low-dose granules

3、Sustained-release granules

4、Instant food and beverage granules

5、Chemical particle preparation

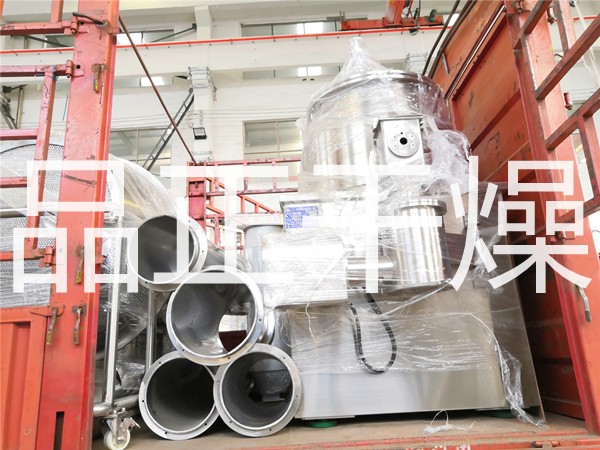

Workshop delivery group diagram